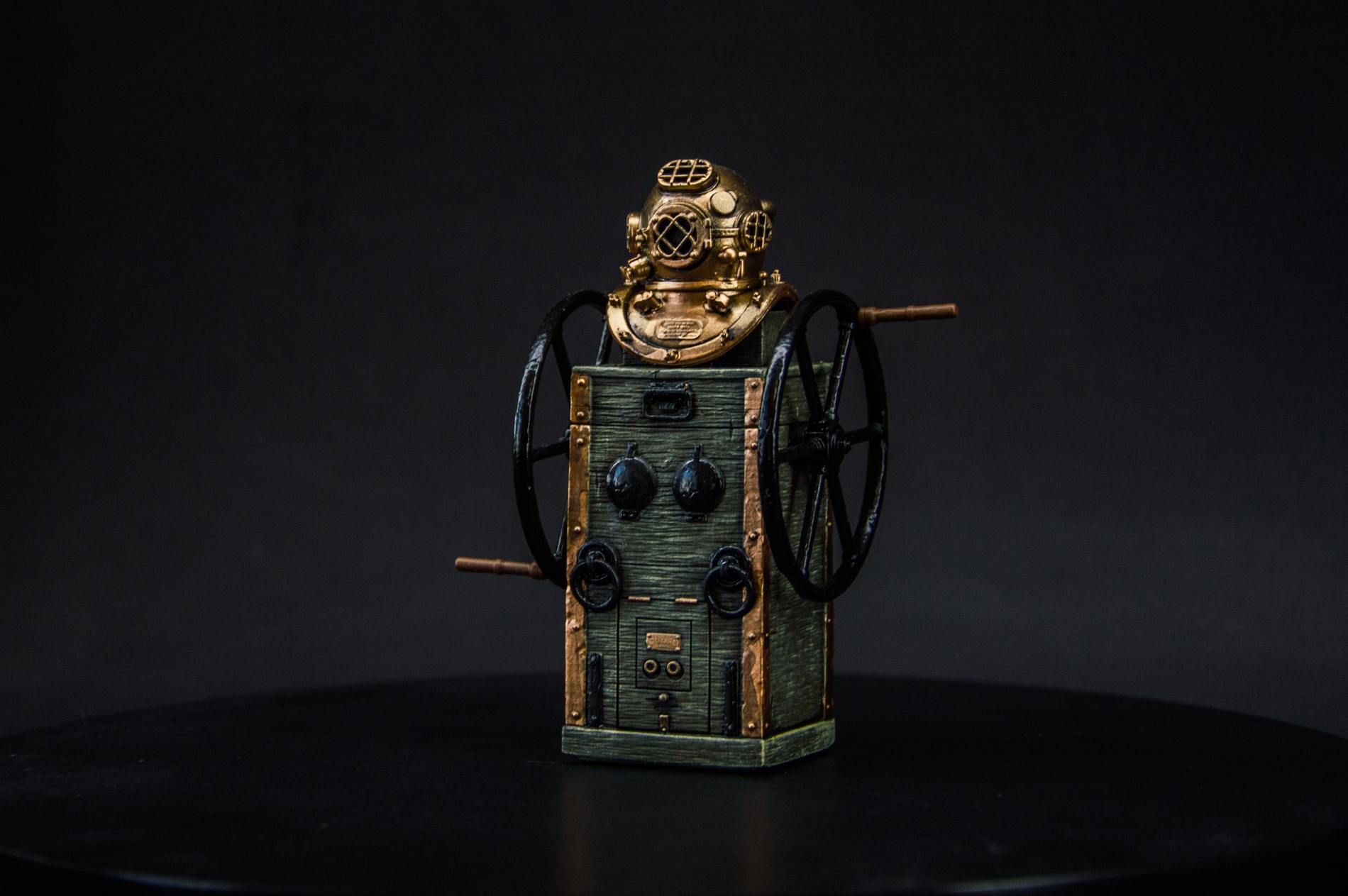

"Old diving pump" it is collectible figurine a diving pump from a last age.

The pump has a professional hand made painting, which reproduces materials such as copper, wood, cast iron. The center of the figurine is filled with metal, thanks to which it is ideally suited as a paperweight.

Historical note

Rotary pumps are driven by a crankshaft that is rotated by handles on two flywheels attached to the ends of the shaft on each side of the pump. Rotary pumps were built with one, two or three cylinders, and are operated by a team of two men. Pistons attached to the crankshaft draw in air through the intlet valves and then pump it through the outlet valves to an air hose which delivers the air to the helmet of the diver. Cylinders, valves and outlet fittings for air are generally made from brass for corrosion resistance in the marine environment. Rotary operated pumps were manufactured with single or double action.

Flow of air through the helmet could be controlled by manually adjusting the back-pressure on the helmet exhaust valve, usually on the lower right side of the bonnet, and by manually adjusting the inlet supply valve on the airline, usually fastened to the front lower left of the corselet. Flow rate would also be affected by the surface delivery system and depth. Manual pumps would be operated at the speed necessary for sufficient air supply, which could be judged by delivery pressure and feedback from the diver. Many manual pumps had delivery pressure gauges calibrated in units of water depth - feet or metres of water column - which would provide the supervisor with a reasonable indication of diver depth. If the diver needed more air, the operators would have to crank faster.